Molybdenum lanthanum alloy (Mo-La alloy) is one of the Moly-REO alloys (molybdenum-rare earth oxide), it is also called rare earth molybdenum or La2O3 doped molybdenum. Molybdenum lanthanum alloy is an oxide dispersion-strengthened alloy.

Mo-La alloy is a useful and important molybdenum alloy composed by adding lanthanum oxide to molybdenum. It has the properties of higher temperature of recrystallization, better ductility, and excellent wear resistance.

Machined Disc/Plate

The recrystallizing temperature of MoLa alloy is higher than 1,500 degrees Celsius.

It can be used in illumination, electric vacuum devices, tube component elements in cathode-ray pipes, power semiconductor devices, tools for manufacturing glass and glass fiber, internal parts in light bulbs, high-temperature heat shields, annealing Filament and Electrode, high-temperature container and component in microwave magnetron.

Mo-La alloy sheets, plates, rods, bar and wire, and machined parts for high-temperature furnaces are available.

Specification for Molybdenum Lanthanum Alloy Wire

| Shape | Wire |

| Material | MoLa alloy |

| Size | 0.5mm-4.0mm diameter x L |

| Shape | Straight wire, rolled wire |

| Surface | Black oxide, chemically cleaned |

Specification for MoLa Alloy Rod

| Shape | Rod |

| Material | Mo, La2O3: 0.3~0.7% |

| Size | 4.0mm-100mm diameter x <2000mm L |

| Process | Drawing, swaging |

| Surface | Black oxide, chemically cleaned, Grinding |

Specification for (Mo-La alloy) Plate

| Shape | Plate |

| Material | Mo, La2O3: 0.3~0.7% |

| Size | 4.75mm-50mm thickness x W x L |

| Process | Forging, rolling |

| Surface | Chemically cleaned, Grinding |

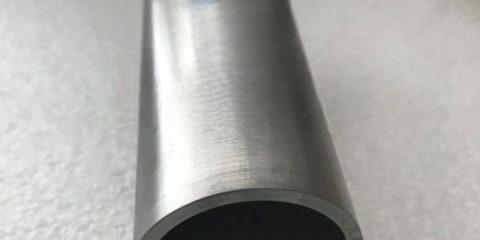

Specification for Molybdenum Lanthanum Alloy Tube

| Shape | Tube |

| Material | Mo, La2O3: 0.3~0.7% |

| Size | 0.8”-20” OD, 106” max length for one piece Mo-La tube |

| Process | Sintering, gun drilling |

| Surface | Finish turning, Grinding |

We can also provide machined alloy parts per drawing, send your drawing to inquiry.crucible@winnewtech.com.

Application of lanthanum oxide doped molybdenum products

Molybdenum lanthanum alloy Tube

– Used in the manufacture of electronic components and semiconductor devices. Its high melting point and excellent conductivity make it an ideal material for manufacturing electronic devices such as electrodes, wires, vacuum tubes, etc.

– Used in high-temperature industrial fields. Commonly used in the manufacture of high-temperature equipment such as high-temperature furnaces, furnace body parts, etc.

– Very suitable for the manufacture of spacecraft parts, such as engine parts, missile parts, etc.

– Due to its high resistance to chemical corrosion, it is used in the chemical industry to manufacture corrosion-resistant equipment such as chemical containers, pipelines, and reactors.

– Play a role in the manufacture of medical devices, especially in the manufacture of medical devices with high temperature and high strength requirements.

Packaging for molybdenum products

The standard package for Mo-La alloy products is a wooden crate so that the products can be protected during handling and transportation. A carton package is also used for small Mo-La pieces.

Please send your request to inquiry.crucible@winnewtech.com, and we will reply you within 3 minutes

inquiry.crucible@winnewtech.com

Non-Ferrous Crucible Inc.

Tel: +86-755-84112759

Fax: +86-755-84112759

No. 7, Gongye 2nd Road, Jinsha, Kengzi, Pingshan, Shenzhen, China.

518122

inquiry.crucible@winnewtech.com