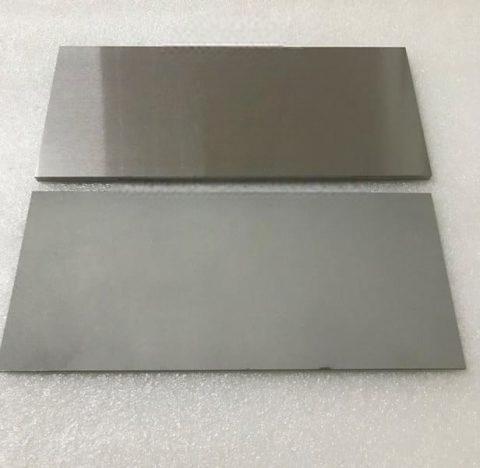

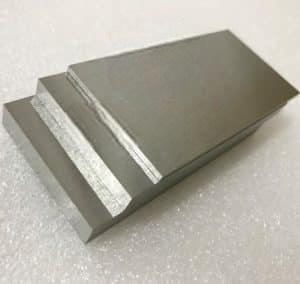

The material is 99.95% pure our sheet and foil are normally supplied as-rolled in thicknesses below 0.030″, and stress is relieved at that thickness and above.

Our tungsten sheets are widely used in ion implantation, medical CT, electronics, and vacuum equipment. We also offer tungsten-based high-density and tungsten-copper composite sheets.

Basic information for W sheets

| Properties of tungsten | Application of tungsten | Surface treatment of sheet |

|---|---|---|

|

|

|

Specifications of our W sheets

| Product | Tungsten Sheet |

|---|---|

| Item No. | PM74-S |

| Purity | W≥99.95% |

| Specification | ASTM B760 |

| Process | Pressing-sintering-Rolling-Annealing-Surface treatment |

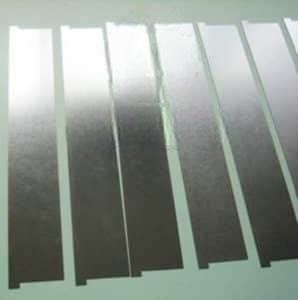

Tungsten Sheet Dimensions (Max, mm)

| Thickness | 0.15-0.20 | 0.20-0.25 | 0.25-0.30 | 0.30-0.50 | 0.50-0.80 | 0.80-1.0 | 1.0-1.50 | 1.50-3.0 |

|---|---|---|---|---|---|---|---|---|

| Width | 205 | 300 | 330 | 350 | 330 | 330 | 300 | 300 |

| Length | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

We can provide sheets with grinding surface, it will need to be thicker than 1.5mm.

Grinding Sheets (mm)

| Thickness | Max Width | Max Length |

|---|---|---|

| 1.5-2.0 | 150 | 200 |

| 2.0-3.0 | 200 | 250 |

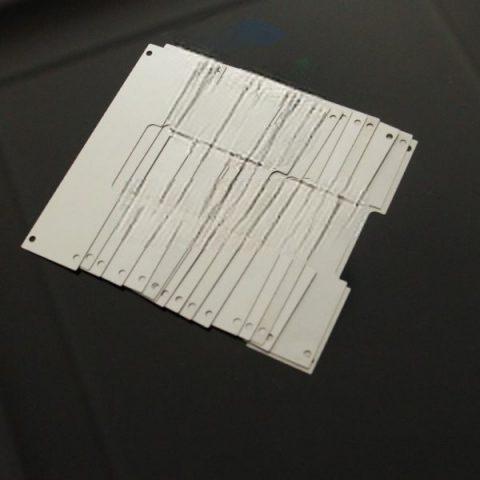

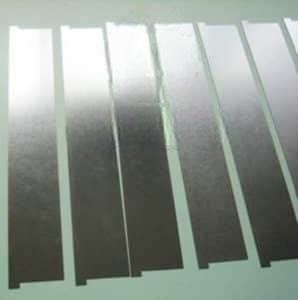

Precision tungsten sheet parts for alpha ray shielding are widely used in medical equipment as detectors, collimators, anti-scatter, and security inspection equipment.

Tungsten Alloy Sheets, WNiFe, WNiCu Alloy

Tungsten Heavy Alloy Sheets contain 90%-97% tungsten and small amounts of molybdenum, nickel, iron, and copper. Like pure tungsten plate, this alloy product begins as a heated powder, mixed, pressed, and sintered to form a metal alloy with unique industrial properties.

For example, tungsten plate’s high density (17-18.5 g/cc), low thermal expansion, corrosion resistance, and high thermal conductivity make tungsten-heavy alloys ideal for many aerospace, military, and medical applications. Its hardness and wear resistance are important for machining tools including lathes and dice. Its ability to absorb radiation is critical to maintaining high performance in radioactive environments.

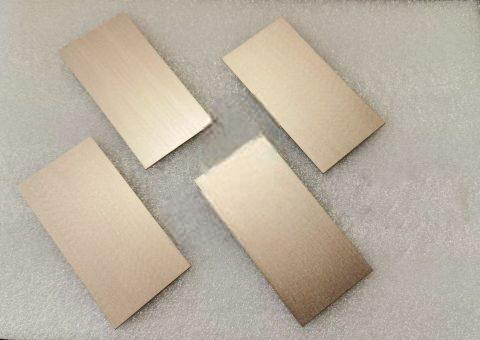

Tungsten Copper (WCu) Sheets

Tungsten copper sheets are the preferred flat materials for high-pressure and high-temperature applications, resistance welding, and EDM applications. This is due to its excellent resistance to heat and galvanic corrosion, its electrical conductivity, low thermal expansion, and good machinability. Pure tungsten has high hot strength and melting point. Copper has excellent thermal and electrical conductivity and is easier to machine than tungsten. Tungsten copper sheets are composed of tungsten and copper with different ratios of W and Cu, mainly including 50/50, 60/40, 70/30, 75/25, 80/20, and 90/10. The wide range of ratio composition enables copper tungsten materials to be easily customized to meet different physical and mechanical properties for different requirements.

Please send us your specifications for tungsten metal to inquiry.crucible@winnewtech.com.

Please send your request to inquiry.crucible@winnewtech.com, and we will reply you within 3 minutes

inquiry.crucible@winnewtech.com

Non-Ferrous Crucible Inc.

Tel: +86-755-84112759

Fax: +86-755-84112759

No. 7, Gongye 2nd Road, Jinsha, Kengzi, Pingshan, Shenzhen, China.

518122

inquiry.crucible@winnewtech.com