Non-Ferrous Crucible Inc. provides molybdenum crucible manufactured by two processes. One is sintered crucible, and its density is 9.8 ~ 10 g/cc, by which way the crucible is sintered directly after molding.

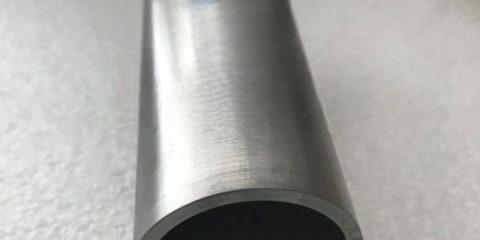

Moly crucible-tapered

The other one is forging, the density of a forged crucible can reach 10.2g/cc. Small crucibles are made with forged rods & ingots.

Mo-La alloy (Lanthanum oxide doped molybdenum) is also used to make high-temperature crucibles, Mo-La alloy crucibles can tolerate higher temperatures (~200℃+) than pure Moly crucibles.

Application for Moly crucibles:

Moly crucible is mainly used in the metallurgy industry and mechanism process industries, and molybdenum is an indispensable material in the rare earth smelting industry. Moly crucibles are more frequently used in crystallized materials and other burgeoning high-technology industries.

Dimensions of the crucible by sintering & forging

| Process | Size (mm) | Tolerance (mm) | ||

|---|---|---|---|---|

| Diameter | High | Diameter | High | |

| Sintering | 10-500 | 10-600 | +/-5 | +/-5 |

| Forging | 10-130 | 10-200 | +/-1 | +/-2 |

Molybdenum crucible types:

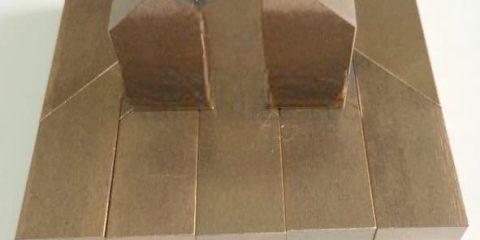

Our company can produce a variety of molybdenum crucibles, such as round crucibles, conical crucibles, oval crucibles, bottomless crucibles, rectangular crucibles, and square crucibles. Crucibles with holes, threaded holes, etc. can be produced according to drawings.

Mo Rectangular Crucible

-Pressed and sintered crucibles

The powder is pressed and sintered into the final shape. They are one of the most popular types of crucibles. Used to make larger crucibles

-Milled crucibles

The material blanks are processed into the final product. This type of molybdenum crucible is also popular. Used to make smaller crucibles.

-Welded crucibles

For larger crucibles with thinner walls, we recommend using welded molybdenum crucibles.

-Spinning crucibles

Large molybdenum billets are formed into specified product geometries by hot spinning.

About Molybdenum

Molybdenum is a refractory metal with the symbol Mo and the atomic number 42. It’s an outstanding material that can meet the most exacting requirements due to its unique mechanical and chemical properties. Molybdenum possesses a very high melting point, a low coefficient of thermal expansion, and a high level of thermal conductivity, it is employed in many different industries.

Molybdenum is used for its extremely high melting point and relative flexibility. Molybdenum has a melting point of 2,623 °C. Molybdenum has a high elastic modulus, and only tungsten and tantalum have higher melting points. Typical applications for Moly are crucibles, evaporation boats, propulsion components, x-ray tubes, the lighting industry, glass melting electrodes, high-temperature furnaces, sputtering targets, heat sinks, heating elements, electrodes, stirrers, orifice plates, support members, mandrels, shields, sintering trays, filaments, furnace windings, thermocouple sheaths, nose cones, nozzles, jet tabs, contacts, brazing fixtures, boring bars, tools, heat radiation shields, cathodes, and aircraft and missile parts and nuclear energy applications where high temperature resistance is crucial.

Please send us your specifications for the molybdenum crucible to inquiry.crucible@winnewtech.com.

Please send your request to inquiry.crucible@winnewtech.com, and we will reply you within 3 minutes

inquiry.crucible@winnewtech.com

Non-Ferrous Crucible Inc.

Tel: +86-755-84112759

Fax: +86-755-84112759

No. 7, Gongye 2nd Road, Jinsha, Kengzi, Pingshan, Shenzhen, China.

518122

inquiry.crucible@winnewtech.com