The coefficient of thermal expansion (CTE) of molybdenum copper can be tailored by adjusting the composition, which is the same way with tungsten copper composites. MoCu is much lighter than tungsten copper, which makes it more suitable for aerospace usage.

Properties for MoCu composites

| Composition | Mo wt% | Cu wt% | Density g/cm3 | Thermal conductivity W/(M.K) |

CTE (10-6/K) |

| Mo85Cu15 | 85 ± 2 | Balance | 10 | 160 – 180 | 6.8 |

| Mo80Cu20 | 80 ± 2 | Balance | 9.9 | 170 – 190 | 7.7 |

| Mo70Cu30 | 70 ± 2 | Balance | 9.8 | 180 – 200 | 9.1 |

| Mo60Cu40 | 60 ± 2 | Balance | 9.66 | 210 – 250 | 10.3 |

| Mo50Cu50 | 50 ± 2 | Balance | 9.54 | 230 – 270 | 11.5 |

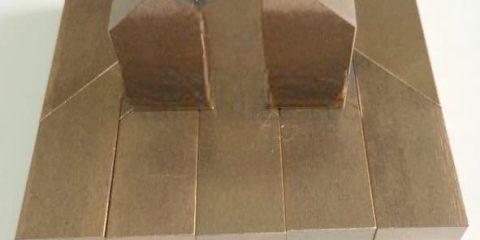

The most important usage of MoCu is heat sinks for electronic devices. We can also provide Mo/Cu/Mo and Mo/CuMo/Mo parts. Visit our Heat Sinks page for more information.

Besides MoCu and (Tungsten copper) WCu heat sinks, we can also provide pure Moly, Cu-Mo-Cu Heat Sinks, Molybdenum-Copper-Molybdenum products, and Cu-MoCu-Cu parts.

Features of our molybdenum copper products:

-No addition of sintering activation elements such as Fe and Co, maintaining high thermal conductivity

-Excellent air tightness

-Low density, more suitable for flight electronic equipment

-Can reduce thermal expansion coefficient

-Special high-temperature performance

-High electrical conductivity and thermal conductivity

-Non-magnetic

-Low gas content, good vacuum performance

-Good machinability

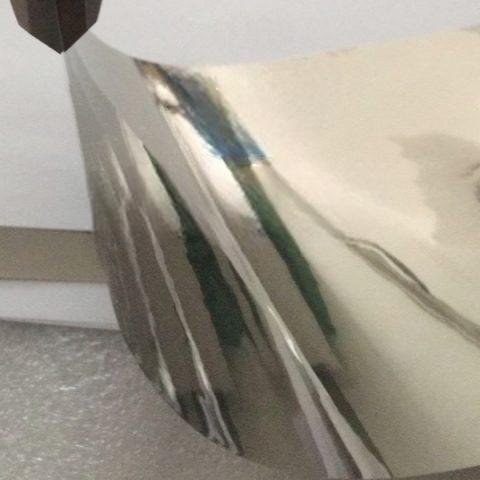

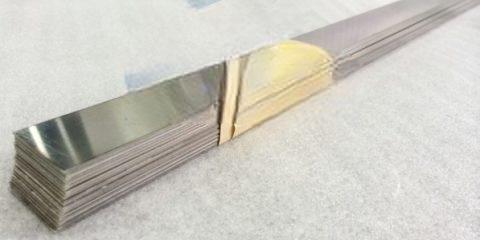

-Rolled plates can be provided when the molybdenum content does not exceed 75%, which is convenient for stamping parts

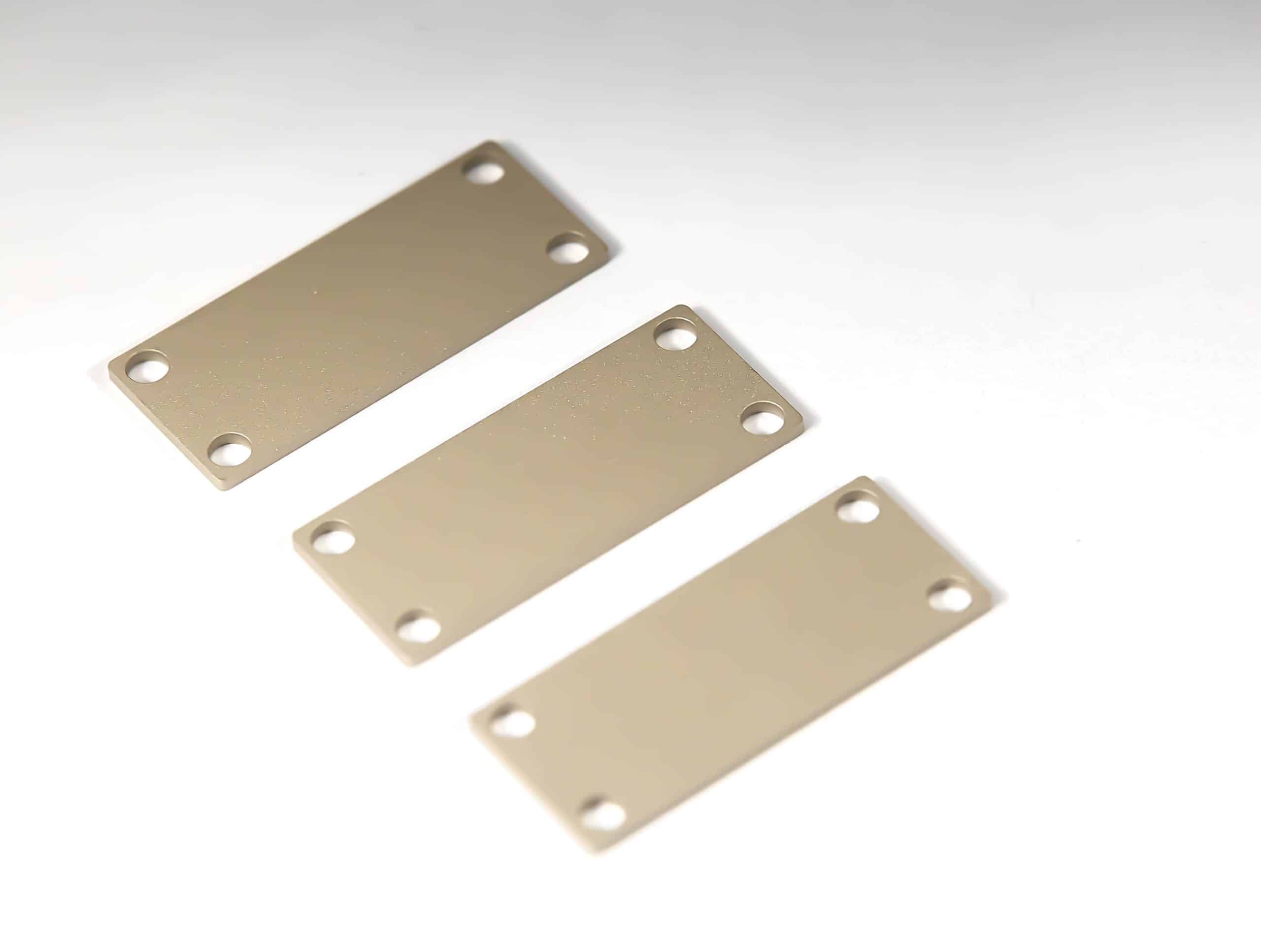

-Provide semi-finished or finished products with Ni/Au surface plating

-Full technical services before, during, and after-sales

Cu-Mo-Cu (CMC materials) Heat Sinks Specification:

| Cu: Mo: Cu (Thick ratio) | Density (g/cc) | Coefficient of Thermal Expansion (10-6/K) | Thermal Conductivity (W/m·K), x-y direction | Thermal Conductivity (W/m·K), x-z direction |

|---|---|---|---|---|

| 1:1:1 | 9.4 | 9.4 | 300~310 | 240~250 |

| 1:2:1 | 9.6 | 7.7 | 260~270 | 210~220 |

| 1:3:1 | 9.7 | 6.9 | 230~240 | 190~200 |

| 1:4:1 | 9.8 | 6.2 | 210~220 | 170~180 |

| 13:74:13 | 9.9 | 5.8 | 190~200 | 160~170 |

Cu-Mo70Cu-Cu ( CPC material) Heat Sinks Specification:

| Cu-Mo70Cu-Cu (Thick ratio) |

Density (g/cc) | Coefficient of Thermal Expansion (10-6/K) | Thermal Conductivity (W/m·K) | ||

| Plate direction | Thick direction | Plate direction | Thick direction | ||

| 1:4:1 | 9.46 | 7.2 | 9.0 | 250-300 | 210-250 |

Application of molybdenum copper composite materials

Due to the above properties, molybdenum copper composite materials have broad application prospects. Mainly:

-Used as vacuum contacts

-Used as conductive heat dissipation components to meet the requirements of high-power integrated circuits and microwave devices for high electrical conductivity, thermal conductivity, heat resistance, vacuum performance, and constant thermal expansion coefficient;

-Used as some instrument components with special requirements, such as non-magnetic, constant thermal expansion coefficient, high elastic modulus, high electrical thermal conductivity, etc.;

-Used for high-temperature components of rockets and missiles with lower temperatures

-Used as solid dynamic seals, reinforcing ribs for sliding friction, water-cooled electrode heads for high-temperature furnaces, electrodes for electrical machining, etc.

MoCu sheet-Au coated

-Wireless communication, metal carriers for wireless communication: tungsten copper molybdenum copper carriers are organically combined with ceramics to greatly improve high-frequency transmission performance

-Optical communication: used for server LSI components, used for communication base stations, etc.

-Semiconductor lasers: LC and LED components

-Power modules: low loss, high heat dissipation efficiency, can be used for high power density modules

The most important use of copper molybdenum is the heat sink of electronic equipment. We can also provide Mo/Cu/Mo and Mo/CuMo/Mo components. Visit our heat sink page for more information. In addition to molybdenum copper and (tungsten copper) tungsten copper radiator, we can also provide pure molybdenum, copper-molybdenum-copper radiator, molybdenum-copper molybdenum products, copper-molybdenum-copper copper parts.

Please send your request to inquiry.crucible@winnewtech.com, and we will reply you within 3 minutes

inquiry.crucible@winnewtech.com

Non-Ferrous Crucible Inc.

Tel: +86-755-84112759

Fax: +86-755-84112759

No. 7, Gongye 2nd Road, Jinsha, Kengzi, Pingshan, Shenzhen, China.

518122

inquiry.crucible@winnewtech.com